The Essential Tool

From drilling machines to excavators, crushing and grinding equipment - the mining industry depends upon having all the right tools. Each type of mining activity comes with its own set of tools. Perhaps the most visible activities, and certainly among the most controversial, are ore crushing and stockpiling. The tools for these activities are conveyors, crushers, and, crucially (pun aside), domes.

Domes improve a mine’s environmental compliance - and its local image. Dozens of mines around the world consider domes essential to affect and demonstrate their environmental friendliness.

No matter how high up on a mountainside the stockpile may sit, Freedomes are the premier means to enclose stockpiles. The raw bulk material may lie within a sprawling and irregularly shaped yard, yet Freedome® technology allows for the design of domes in any shape and on any terrain.

Domes can be designed in different profiles - circular, elliptical, parabolic or a combination of different curves. Long-span, column-free and large volume structures are our specialty.

Having a column-free interior allows for the free-flow of personnel, vehicles, conveyors and other essential equipment — often while the pile is in operation. This equates to zero downtime and enables mines to continue production even while the bulk storage solution is being constructed.

Every mining operation is different, but through the years, our structures have changed mining practices by overcoming seemingly insurmountable issues with a distinct solution. For example:

Fugitive dust

Completely cover circular stockpiles up to 300m diameter or longitudinally up to 100m wide without any interior columns.

Irregular piles or terrain

Exclusive Freedome design technology fits odd-shapes piles on uneven terrain.

Zero downtime

Stockpiles remain in operations during installation without any loss of production.

100% prefabricated components

Easy assembly by local crews saves time and money.

Dense packing volume provides standard shipping to remote locations.

Galvanized steel or aluminum alloy parts

Corrosion-resistant, lightweight, and cost-efficient.

Structure Design

Strong and durable to withstand typhoon-force winds and grueling snow loads.

Signature Projects

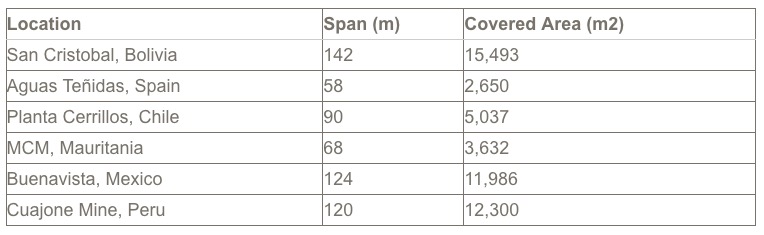

Extremes of altitude, slope, climate, and shape are no match for our patented technology and quality-controlled process (ISO 9001:2015 certification). Here are some examples;

Located in the Andes Mountains, the San Cristobal dome was erected around a live stockpile in an irregular shape with no downtime. The dome is designed to withstand wind speeds of up to 150 kph and an ice load of 110 kg per square meter. It accommodates a 9m change in elevation over an astounding 140m, fitted to the terrain.

Geometrica designed two domes for Minas de Aguas Teñidas S. A. (MATSA) in Spain. These Andalusian “twins” stand 29m high and 58m diameter. Each dome has 14,400 tubes and 4,100 connectors with two openings, one for the feeding conveyor ingress and the other for heavy machinery.

Approximately 30km southeast fo Copiapó City, dust from ore handling and crushing was smothering the landscape and vineyards. Planta Cerrillos had used foam sprays and fabric barriers, but they were ineffective. It was time to cover the plant. Geometrica’s free-style dome was the perfect solution to contain a sprawling stockpile and existing machinery.

In Northwestern Africa, Geometrica designed and installed a circular mineral storage dome for Mauritanian Copper Mines (MCM) spanning 68m. Managing air quality and dust are closely monitored by MCM on a monthly basis, both inside and outside of the mine site boundary. The mine is located 250 kilometers northeast of the nation’s capital, Nouakchott, near the town of Akjoujt.

Buenavista first installed an 88m Geometrica dome to cover their crushed material stockpile to prevent dust from escaping into the environment. 15 years later, growing operations required a new stockpile and a new dome. The dome was built on a 6m high concrete wall, and around a stacking conveyor that was scheduled to be built before the dome.

Covering the copper ore was part of Southern Peru’s overall initiative to reduce operating and maintenance costs as well as the environmental impact of the Cuajone Mine. This project involved the design of a super-structure that incorporated three of our structure types - an arch vault, half-dome, and end wall.

These are just a few examples of our light-weight, durable - and, equally beautiful storage structures. For over 25 years, Geometrica has delivered unique solutions for some of the world’s most complex mining projects.

From the Middle East to Asia, Africa, and the Americas, Geometrica is the leading expert in geodesic dome technology. Regardless of heavy snow loads, brutal slopes, corrosive saltwater or hurricane-force winds, we offer endless design solutions that can become one of the most essential tools available for a mining operation.

We believe that mining can put a stop to the controversy, improve environmental compliance and be a good corporate citizen without breaking the budget - sustainably!

The question is, “What’s that tool in your mine?” To learn more, please complete our inquiry form and let’s get started.