Gridshells: Free-form and Free-span Buildings

A gridshell's organic shape and column-free space provide unlimited design freedom to architects and structural engineers. These innovative space-frame structures derive their strength from having double curvature in their overall shape. In that, they are similar to geodesic domes. But while geodesic domes are limited to spherical surfaces, gridshells may take on different curvature in each of two orthogonal directions.

Artful use of geometry allows lightweight gridshells to span vast expanses of space. They provide all the efficiency of geodesic domes, but with playful forms and whimsical support conditions. Gridshells are also known as free form domes, freestyle domes, lattice shells, or reticular domes. Geometrica calls its gridshells "Freedomes®", its registered trademark for these structures in use since the mid 1990s.

History of the Gridshell

Gridshells have an interesting history. The name "gridshell," particularly in Europe, became a way to describe free form combinations of dome-type curvature and inverse curvature in a single lattice. But, at first, gridshells had either positive curvature, as geodesic domes, or negative curvature as hyperboloids. In the closing decade of the 19th century, Russian engineer Vladimir Shukhov built tall towers with criss-crossing straight line generators that formed hyperboloids of revolution. In the late 1920s, Walther Bauersfeld created the first geodesic dome as formwork for a planetarium in Germany, and subsequently, Buckminster Fuller started popularizing this form in the 1950s.

In February of 1965, Dr. Douglas Wright (Founding director of Geometrica) published a seminal paper on the design of gridshells, Membrane Forces and Buckling in Reticulated Shells in the Journal of the Structural Division of the American Society of Civil Engineers. It explained how these beautiful structures could be engineered based on sound principles of mechanics, even before computers were sufficiently powerful or available. It became the Structural Division's most discussed paper to its date, and enabled the rational use of this structural form.

Using that research, F. Castano Sr. (father of Geometrica's CEO) and Wright collaborated in several hyperbolic paraboloid gridshells in the late 60s, including the Mexican pavilion at Expo 67 in Montreal, the 1968 Sports Palace in Mexico City, and various other showcase buildings.

Perhaps the first true free-form gridshell was the Toluca Auditorium. The architects were Gallo and Azorin, and the engineers Wright and Castano Sr. It was conceived as a rectangular-plan building, with an arbitrary, non-algebraic surface lattice that had a continuously-varying radius of curvature. Castano's firm, the precursor to Geometrica, built this remarkable gridshell in 1967. The result was stunning. It won Mexico's National Architecture Award in 1967.

Geometrica carries on this heritage to this day by building long span and light weight gridshells worldwide for architectural and environmental protection markets.

Geometrica's gridshells do take advantage of 3-dimensional structural behavior to achieve architectural and budgetary goals in construction projects, as explained further on. But first, a comparison:

Gridshells vs Geodesic Domes

It is well known that the spherical surface of geodesic domes encloses the maximum volume for a given surface area. But the volume of a sphere, or even a segment of a sphere, while ideal for material storage, is not so useful for many other activities, and could result in wasted land or space.

For many applications, a spherical section is either too tall at the center, or too low at the edges, unless the edge of the dome is raised with a wall or columns. In a gridshell, the profile may be adjusted so that it raises quickly, to provide a reasonable eave height, and then spans with a low slope, to save on unusable space. Gridshells may be surfaces of revolution of positive curvature, or of negative curvature, or of both.

There is literally an infinite number of possible plans for a gridshell. Some of the more common are variations on the rectangle, but triangles, stars, ovals and other shapes are possible. A meridian may be parabolic, elliptical, circular, or any other smooth curve. The spring line may be Seussian in plan or elevation. This freedom of form provides for efficient use of land and for beautiful interior space. Bucky would drool.

Another example: hyperboloid water towers have negative curvature and optimized geometry for elevated water containment. And turning this shape over yields elegant roofs.

Designing Long Span Gridshells

One simple algorithm to find the form of single-span gridshells requires only four parameters:

Border of dome

Height at apex

One meridian

Angle in plan about which the selected meridian is taken.

To adapt to the changing edge of the dome, the meridian will vary as it is examined in other directions. But drawings need show only one of the sections in order to completely define the geometry. Once the geometry and support conditions of your structure are defined, Geometrica engineers can propose the most efficient patterns and layer options for your enclosure, or you may choose the pattern yourself. Other form-finding algorithms are also possible. For example, a gridshell form may be found by mathematical relaxation methods, or by physical analogies, such as minimal surfaces or tensile grids.

Supports may be concrete or steel columns, walls, edge beams, or slabs. The dome may be reinforced with an integral tension ring to withstand its horizontal reaction due to gravity loads. Other interesting variations on basic gridshell shapes, include:

The spring line of a gridshell may vary in elevation when desired. This may allow side support, corner support, or higher edges for special openings.

Setting the apex off-center may be useful when one side is not supported, for instance in an amphitheater or an aviary.

Another variation of an efficient Freedome® is a minimal surface; as the word describes it, it is the least surface necessary to cover a particular boundary. It can be achieved by varying the support heights. Other variations to a minimal surface can be achieved by applying a load to “dome” it. For example, water tanks can be built in the form of a drop of water, whereby the shell surface achieves uniform tension.

50 years up, 50 years coming

In the years since Douglas Wright conducted his seminal research, computers became available and gridshell building became popular. Architects around the world can imagine and draw amazing, curving surfaces that span hundreds of meters without intermediate supports. Light is brought into interior space as never before thanks to the airiness and slenderness of metallic gridshells. But one problem still makes gridshells less prevalent than the form warrants. Their structural efficiency did not translate well into budgetary efficiency: it has been too difficult and costly to manufacture and assemble structures with hundreds of thousands of components where every single part is different from every other. For this problem, and despite their potential, gridshells have often been restricted in their use to very high-profile projects with large budgets.

But Geometrica has solved this problem. With Geometrica's system of construction and Freedome® technology the inherent structural efficiency and beauty of gridshells is available to all projects. Built of lightweight and strong galvanized steel or aluminum, Geometrica gridshells can and have been used in purely functional applications, just as well as for those architecturally distinct buildings.

Geometrica structural tubes are prefabricated in a computer-based manufacturing system and connected on site with its efficient aluminum hubs. The hub provides for unlimited variety in form. Individual parts are stamped, computer-labeled, and packaged for efficient use in the field. Ductile behavior is achieved, as the joint develops 130% of steel tubes' rated yield strength and transfers bending. When all tubes for a hub have been assembled, the joint is finished with washers and a single bolt.

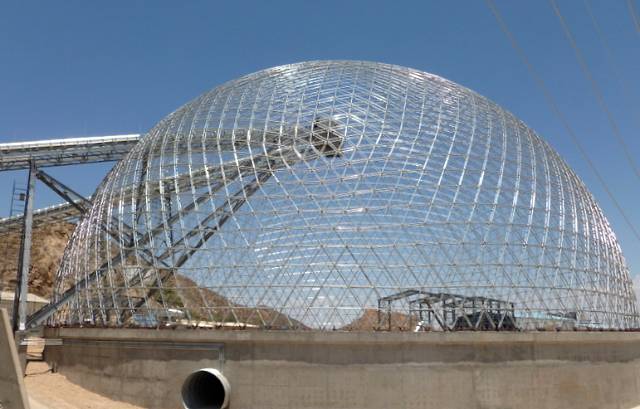

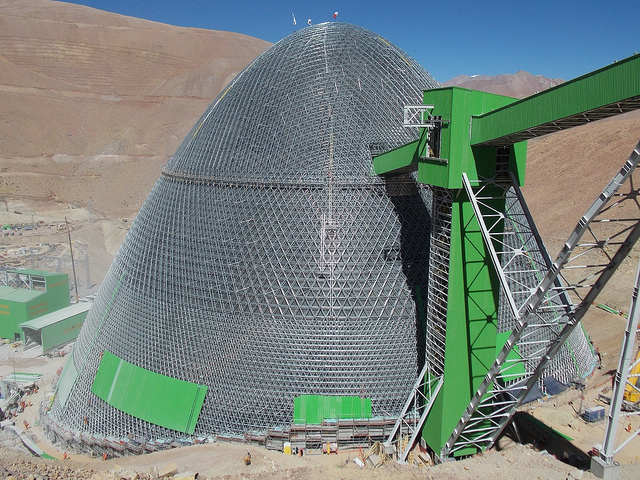

Geometrica has built the largest industrial gridshell domes in the world using Freedome® technology, achieving up to 18,000m2 of cover area and major axis spans of 224m (pictured above), or 145m diameter and 94m height (pictured below). Other examples include the lucky Freedome coal dome in Taiwan, the twin 122m domes for JEA in Florida, the 5000m2 Coemin Freedome, the 135m Ruwais dome in Abu Dhabi and the 140m San Cristobal Dome in Bolivia.

The next 50 years of gridshell construction will be exciting indeed.

Geometrica is a world leader in vaulted and free-form architecture, geodesic domes and gridshells. Fill out the inquiry form to get more information about how Geometrica can help in your project.