Free Form Cladding Options - Insulation

In our previous article, we discussed different cladding options for the Exterior Face of free form structures. Here we continue with the design of the envelope integrating a variety of options that will make your building comfortable and beautiful.

Comfort is valued most when missed. It impacts the experience of the users of architectural spaces and the productivity of industrial facilities. It must be planned-in. A major feature in achieving a comfortable building is judicious choice of thermal insulation and acoustic treatment for the envelope. Many types of thermal and acoustic systems are possible in the Geometrica Freedomes®, even in projects with the most complex and demanding forms. Take a look at the following examples and get comfort for you and your building's visitors.

1. Fiberglass mat. This provides basic thermal and acoustic insulation at an affordable price. It can be installed between the roof and the structure as shown in the diagram of the GR-22 system, or between the layers of the Geometrica structure as seen in the photograph taken during the installation of the DSWMC in Qatar. Fiberglass mat can have a vinyl facing that acts as a vapor barrier and allows it to be exposed to the interior, and thereby omit a ceiling.

Fiberglass can be accommodated between the layers of the structure. The space between layers can range from 400mm to 1500mm (16” to 5’).

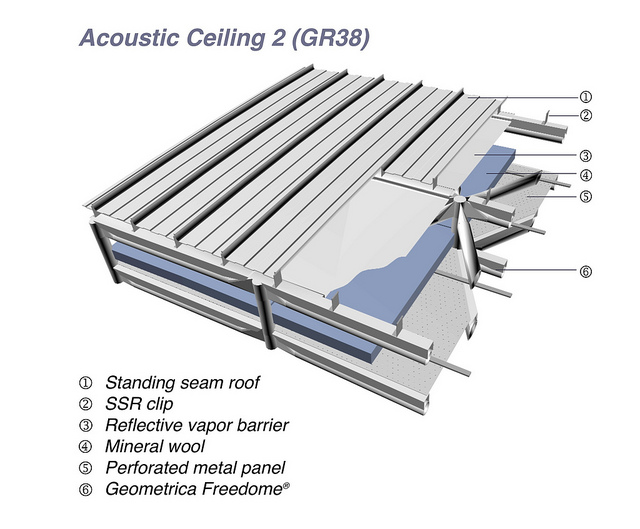

2. Mineral wool. It has a slightly better thermal and acoustic performance than fiberglass, with the advantages of being stiffer, denser and act as a firewall. It should be installed between the layers of the structure and not faced with vinyl. For best interior appearance, expanded or perforated metal can be used as facing. Sample systems with mineral wool would be GR-33 and GR-38.

3. Sprayed-on insulation. This can be a polymer, mineral or cellulose. Interior finish can be drywall, wood or other interior panels. This solution was used in the Soumaya Museum, where layers of polyurethane and cellulose were covered with sheetrock.

Sheetrock was used as interior cladding for the Soumaya museum.

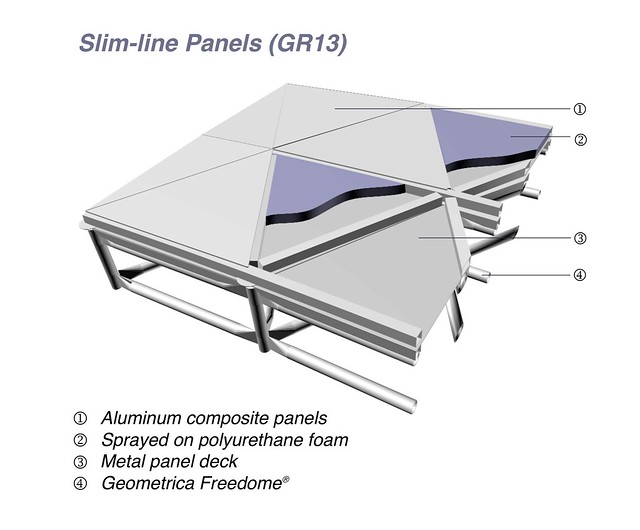

4. Individual panels. When using a panel support system, such as GL-48 or GR-13, the panels themselves can provide thermal insulation, be it with insulated glass or with metal-faced sandwich panels.

In Bangladesh, the new Auditorium at the National Science and Technology complex will use a combination of safety glass panels and aluminum-sandwich panels with a polyisocyanurate core.

5. No insulation. If acoustics are not a concern, in hot climes it may be possible to omit insulation and still obtain satisfactory temperature within a dome. A dome houses a cushion of air. Hot air raises and cooler air sinks to the floor area, where people are. This is called "air stratification" and it helps make domes very popular in warmer regions.

As you can see, there are multiple possibilities for your doubly-curved building envelope. Having covered in these two articles the options for the exterior and the core of the structure, in our next article, we will review different ceiling options for interior appearance we have used in our projects.

Contact us, Geometrica will be happy to work with your design team in coming up with the perfect cladding solution. We are sure you will find that cladding double-curvature can indeed be double-comfortable.