Bulk storage

Mineral Ores

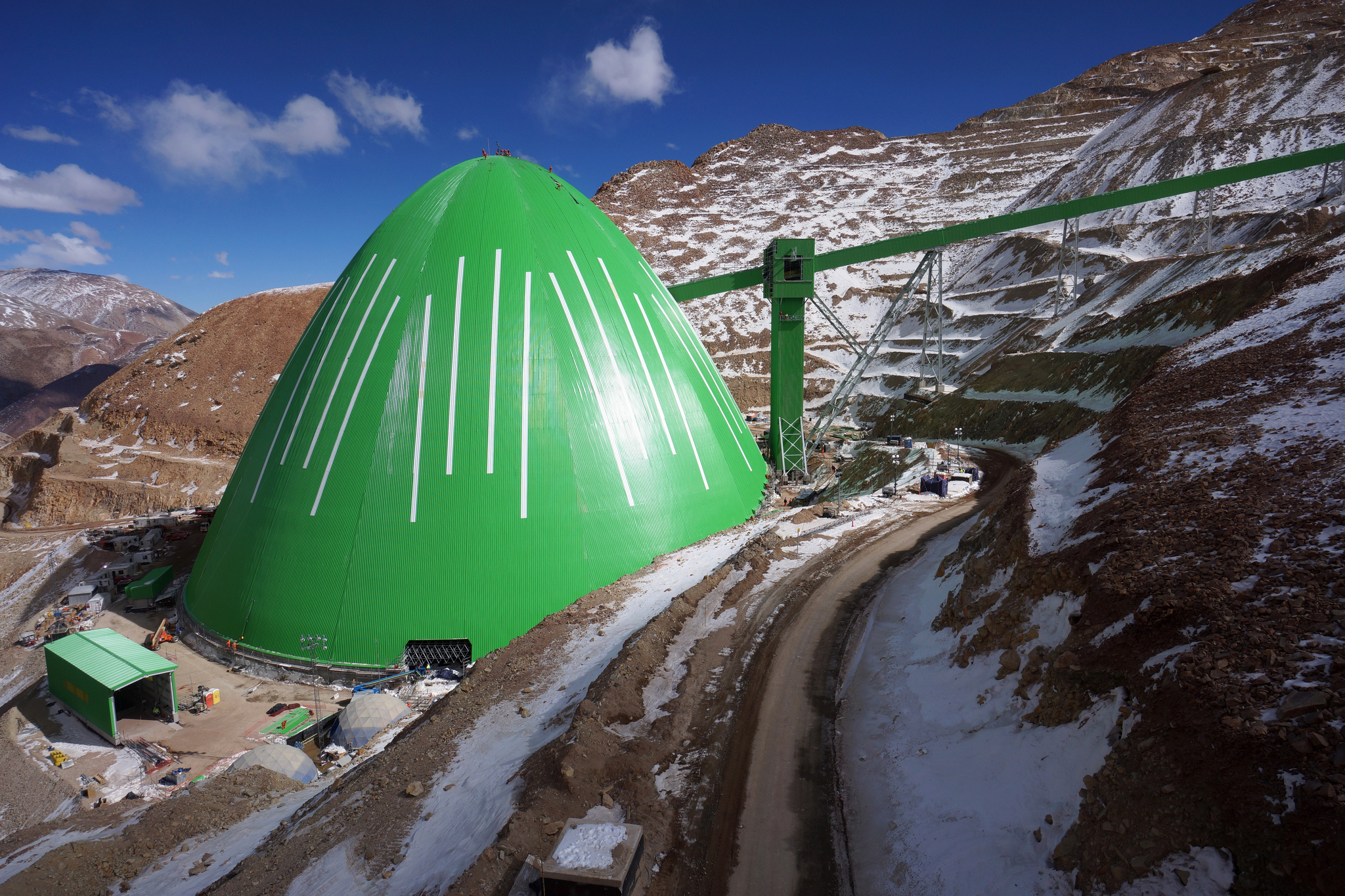

Mining companies face the toughest environmental and permitting challenges. Geometrica helps meet both with elegant, versatile domes.

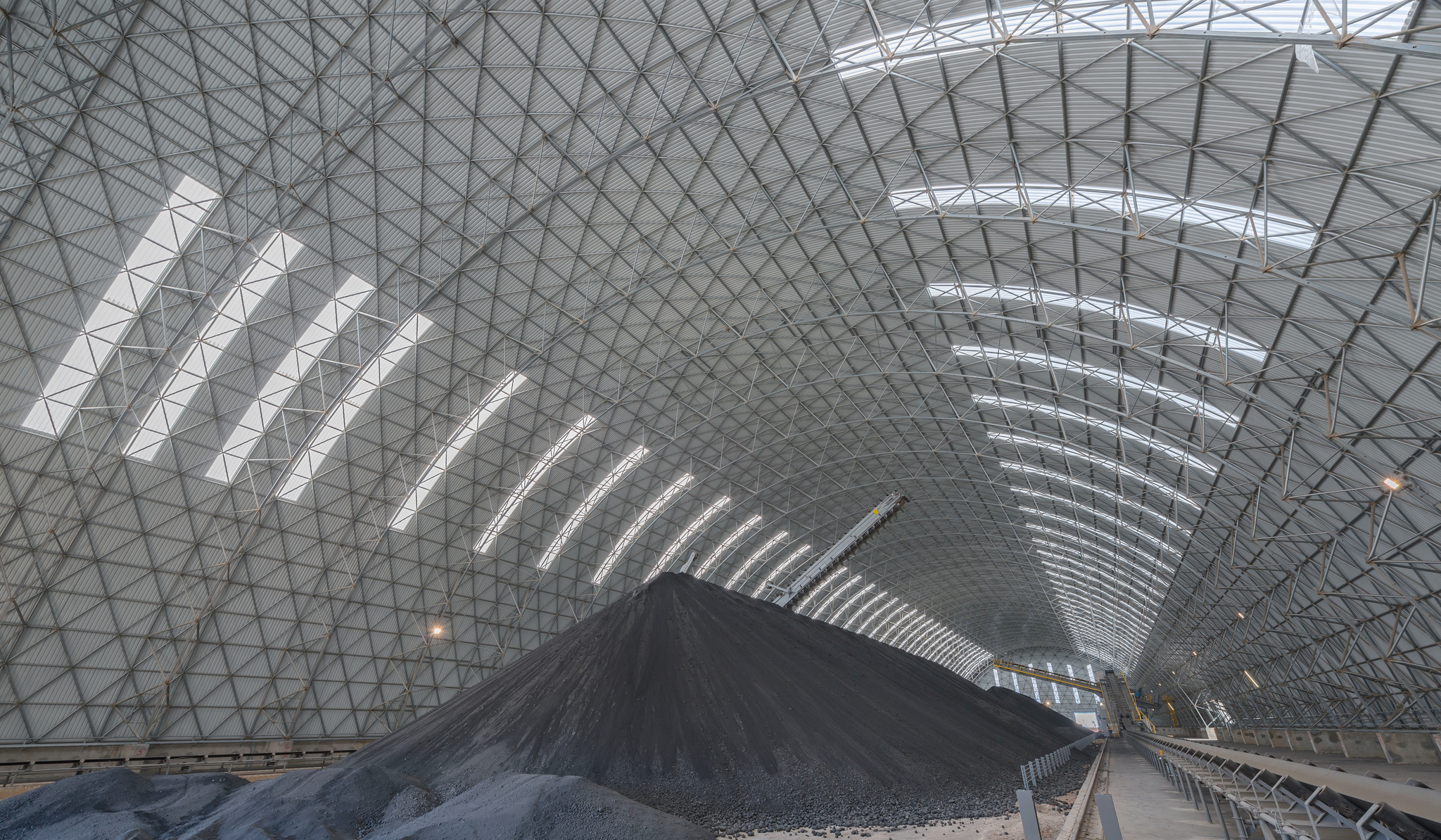

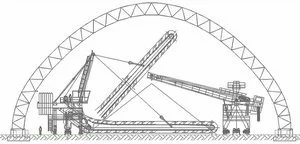

Ore stockpiles house immense volumes and produce dust. They sit on sloping terrain at inaccessible locations. They are irregular in shape. And, often, they are already in operation.

Geometrica domes can be built to meet every one of these challenges. Dust is controlled and your property becomes attractive to clients, investors, regulators and neighbors alike.

A Geometrica dome solves your stockpile dust problem.

Geometrica domes can be built without stopping production.

Below we see the Herradura twin domes built over operating stockpiles.